This article, Part 2 of Welding Digest’s three-part series on beam welding, looks at two common beam welding types. Read Part 1 here.

Laser welding systems focus high energy beams from CO2 gas lasers, solid state lasers (Nd:YAG), disk lasers and fiber lasers to melt and join components. Laser beams are focused with lenses or reflective optics in the laser head or focusing unit.

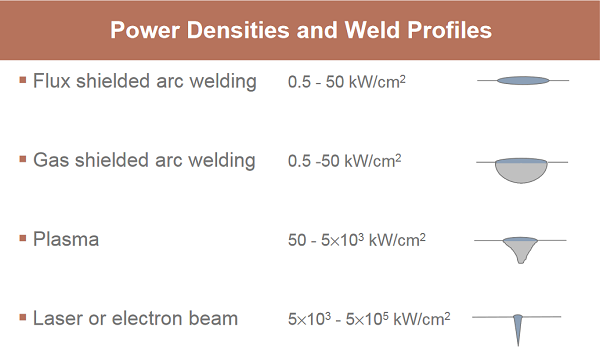

Figure 1: Power densities and weld profiles of arc, laser and electron beam welding. Source: U.S. Nuclear Regulatory Commission (NRC)

Figure 1: Power densities and weld profiles of arc, laser and electron beam welding. Source: U.S. Nuclear Regulatory Commission (NRC)

The beam motion along the joint is controlled by galvanometers, deflectors, MEMS scanners or flying optics in the scan head. Fiber optic beam delivery systems and fiber lasers enable laser welding to be performed at remote locations by delivering the beam from the bulky laser system through the fiber to the joint. Laser welding system can use continuous wave or pulse beams. Laser beam pulsing can adjust the heat input during welding enabling very small penetration as small as 0.03 in. Laser welding can create a much deeper and narrower weld with a smaller heat-affected zone (HAZ) compared to arc welding processes. Current does not pass from the laser beam to workpiece, so plastics, ceramics, glass and other non-conductive fusible materials can be or have the potential to be laser welded.

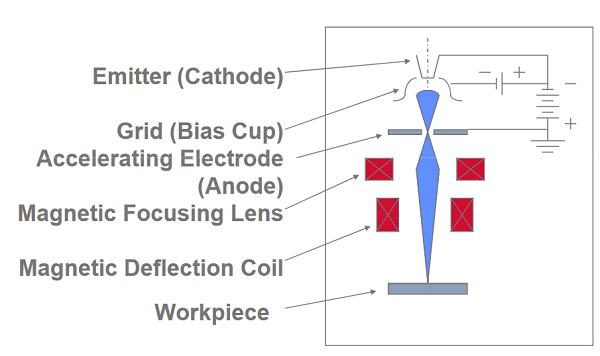

Figure 2: Schematic of an electron beam welding machine. Source U.S. NRCElectron beam welding can produce even narrower and deeper welds than laser welding because electrons have a smaller wavelength compared to light waves or photons. The narrow, deep electron beam welds minimize HAZ and weld thickness. In electron beam welding systems, electrons are generated at a cathode, accelerated with a high voltage potential and then focused with electromagnetic lenses. Additional scanning electromagnets can then control the position and movement of the beam along the joint seam.

Figure 2: Schematic of an electron beam welding machine. Source U.S. NRCElectron beam welding can produce even narrower and deeper welds than laser welding because electrons have a smaller wavelength compared to light waves or photons. The narrow, deep electron beam welds minimize HAZ and weld thickness. In electron beam welding systems, electrons are generated at a cathode, accelerated with a high voltage potential and then focused with electromagnetic lenses. Additional scanning electromagnets can then control the position and movement of the beam along the joint seam.

While laser welding can be done in the air, parts must be placed in a hard-vacuum chamber for most electron beam welding because air would scatter and absorb the energy of the beam before it reached the workpieces. Vacuum chambers hinder electron beam welding applications because workpieces must be moved into the chamber and positioned, and the chamber must then be pumped down, which lengthens cycle times. Some electron beam welding is performed in partial or soft vacuum and non-vacuum conditions. The penetration depth declines as the vacuum quality moves from hard to partial or soft to non-vacuum.

The electron wavelength or beam size is dependent on the accelerating voltage. Electron beam welding requires a high voltage power supply. The high voltage can pose electrocution hazard if not properly maintained, which is a disadvantage compared to laser and conventional welding. Another drawback of electron beam welding is generation of x-ray occurring when electrons strike a metal or material. The x-ray radiation can be damaging to operators, so proper shielding is required to protect workers. Electron beam welding has longer cycles times compared to laser welding due to the more complicated setup and moving parts in and out of vacuum chamber. The properties of electron beam weld metal are much closer to parent metal properties compared to most other welding processes.

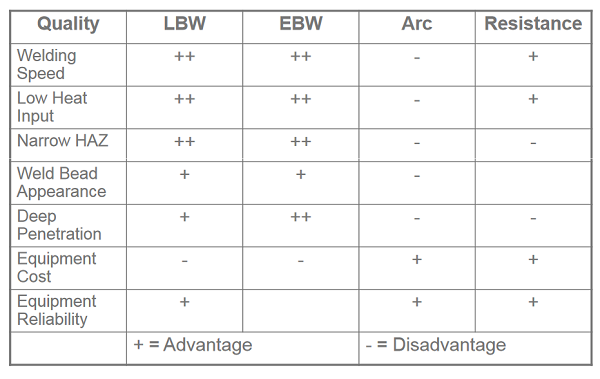

Figure 3: Comparison of laser, electron beam, arc and resistance welding processes. Source U.S. NRC

Figure 3: Comparison of laser, electron beam, arc and resistance welding processes. Source U.S. NRC

Highly reflective metals like gold, silver, copper and aluminum require higher heat input during laser welding until melting occurs. The high conductivity of copper makes arc welding copper difficult. Electron beams can produce deep, high integrity welds in copper, which is difficult to weld with conventional arc and laser processes.

Beam welding as many advantages and some disadvantages compared to conventional arc welding.

In the next part of the series, some beam welding applications will be reviewed.

聯(lián)系人:Rob

微信:18666076565

手 機(jī):18925189619 (In Mandarin, Cantonese & English)

電 話:020-31190575

郵 箱:sales@gzyuto.com

公 司:廣州粵拓機(jī)電設(shè)備有限公司

地 址:廣州市番禺區(qū)橋南街蜆涌村市南路653號(hào)102

網(wǎng)站: m.graaaaaagh.com